IIoT Solutions Delivering Significant Benefits

Average ROI from Some of Miniotec’s Recent IIoT Digital Transformation Projects

.png)

Case Studies - Remote Condition Monitoring (Rotating and Static)

Iron Ore Mining Company

Challenge:

Ore build-up on the vibratory feeder pan frequently caused contact with the static chute, leading to structural cracks and catastrophic failures. Each failure resulted in ~6 hours of lost production plus repair costs.

Solution:

Shortly after installation, two chutes on separate dates triggered notifications of rising velocities. Upon inspection, the maintenance team identified build-up at the back and sides of the feeders, leading to increased vibration. Preventative cleaning of the chutes was performed, averting potential structural failures.

Thermal Power Plant

Challenge:

The client was experiencing unplanned downtime on at least three (3) occasions in the past year. Estimated $250,000+ loss in revenue each day of downtime.

Solution:

IIoT sensors were installed within the operating power generation facility. The technology detected a start of vane pump failure within six (6) weeks of installation.

Large Tier 1 Global Miner

Challenge:

The client needed a reliable solution to identify and address potential bearing defects on critical conveyors within their Outflow Circuit. There were concerns of unplanned downtime and costly production losses and repairs.

Solution:

The Wireless vibration monitoring system was installed on their conveyor network. These sensors, integrated with predictive analytics, flagged an emergent condition on a conveyor’s pulley. The condition monitoring team confirmed the sensor's alert, allowing for early detection and proactive maintenance, thus preventing a potential failure and supporting their data-driven decisions process.

Steel Manufacturing Company

Challenge:

Effective condition monitoring is crucial to prevent unexpected equipment failures and reduce downtime. The client needed a reliable system to detect potential bearing faults in critical equipment, particularly those in areas not readily accessible or in hazardous locations, before they could cause extensive damage.

Solution:

The IIoT sensors autonomously identified a fault pattern in the Motor DE bearing, specifically pinpointing the type of bearing fault (BPFO). This early detection allowed for timely, data-driven maintenance decisions, preventing the possibility of extensive damage and affirming the value of the IIoT solution.

Global Iron Ore Miner

Challenge:

The client faced a significant risk of undetected equipment issues due to reliance on manual monthly monitoring. A layshaft bearing on a crusher, offline for a modular shutdown, showed a sudden increase in vibration, which could lead to catastrophic failure if not addressed promptly.

Solution:

An IIOT sensor detected the vibration increase almost immediately after the plant restarted and sent an immediate alert. The condition monitoring team confirmed the issue, identifying ore buildup inside the pulley itself. They issued a repair notice to remove the buildup, preventing potential failure and avoiding an estimated $300k in operational and mechanical losses.

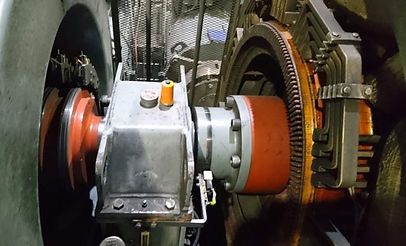

Coal Mining Company

Challenge:

A Client was experiencing persistent failures in their in-plant generator. Estimated loss due to downtime with each failure: $160,000 per day.

Solution:

In order to ensure the system was monitored overall and that vibration energy was not being transferred from elsewhere, IIoT sensors were rapidly deployed throughout this and other auxiliary equipment. Within 13 days, they detected a brush failure in the generator.

International Airport

Challenge:

Failures on complex baggage handling equipment have a major impact on flight schedules and passenger satisfaction.

Solution:

IIoT sensors were installed within their facility detecting the fault in the motor bearing within one (1) week. A basic $65 bearing was replaced during a regular maintenance shutdown instead of having a $5,000 gearbox fail during peak usage.

Fertilizer Plant

Challenge:

A Client was experiencing persistent failures in two (2) of their plant motors. Estimated loss due to downtime with each failure: $150,000 per day

Solution:

The Wireless Vibration IIoT sensors were installed within their facility and detected a bearing outer race failure within six (6) weeks of installation.

Case Studies - Fluid Condition Monitoring Sensor

Wind Generation

Challenge:

Planetary bearing faults, make up a majority of wind turbine generator failures. They are difficult to detect during their early stages and are typically managed through end of life using vibration systems alone.

Solution:

Traditional borescope methods could not locate any fault. The wear debris sensor was deployed to assess and monitor fault severity. We observed abnormal wear levels shortly after deployment. Total savings: >$250k

Coal Mining Operations

Challenge:

A high percentage of coolant leaks are not detected early enough using periodic oil samples, causing secondary damage or catastrophic failure of the engine.

Solution:

Using Miniotec's offered oil quality sensor, the operator can detect oil problems immediately, eliminating secondary damage and catastrophic failure. The oil sensor was installed to provide continuous online oil health so as to immediately detect faults otherwise missed by offline analysis and between planned maintenance activities.

Case Studies - Next-Gen Time Management and Project Controls

Time and Resource Management

Challenge:

The organisation struggled with delayed and incomplete time capture, which obscured true labour costs and hindered timely insight into project performance. Without reliable week-end submissions, leaders lacked the data needed to compare actual spend against budget and make informed decisions..

Solution:

Deployed in just days, the Timesheet module seamlessly onboarded internal teams and external contractors, automating reminders and simplifying entry workflows to achieve 95% compliance by week’s end. Real-time dashboards now display actual vs. budget metrics instantly, empowering managers to reduce overruns by up to 14% and realise over >$200k in annual savings.

Project Control and Budget Oversight

Challenge:

The mining operation depended on fragmented spreadsheets and complex macros for project planning and progress tracking across pit and processing units. Manual data consolidation introduced version-control conflicts, calculation errors, and reporting delays—leaving site engineers blind to schedule slippage, cost overruns, and emerging risks, impacting production and compliance targets.

Solution:

We replaced spreadsheet-based workflows with the integrated, mobile-enabled project controls suite—centralising baseline schedules, cost ledgers, resource plans, and risk registers into a single dashboard. Field crews now log excavation and processing metrics in real time, while automated alerts surface variances against plan. This shift delivered a 20% uplift in schedule adherence, cut budget overruns by >10%, and unlocked roughly $1 million in annual cost savings. All at only one site.

Case Studies - Digital Transformation in Asset Lifecycle Management

Empowering Clients with Data Centric Thinking

Challenge:

Traditional project design, execution and operation methods heavily rely on manual processes, document-centric systems and paper-based workflows. This approach leads to inefficiencies, design inaccuracies and slow execution. Outdated systems also pose security risks and limit the integration of new technologies, making it difficult to manage and leverage data effectively.

Solution:

Miniotec supported in strategy development and implemention of end-to-end digital consulting services, integrating data from various sources to create a unified, data-centric view. This approach reduced project deliverables, improved data quality and enabled efficient, real-time decision-making, significantly lowering total installed and ongoing operational costs.

.png)